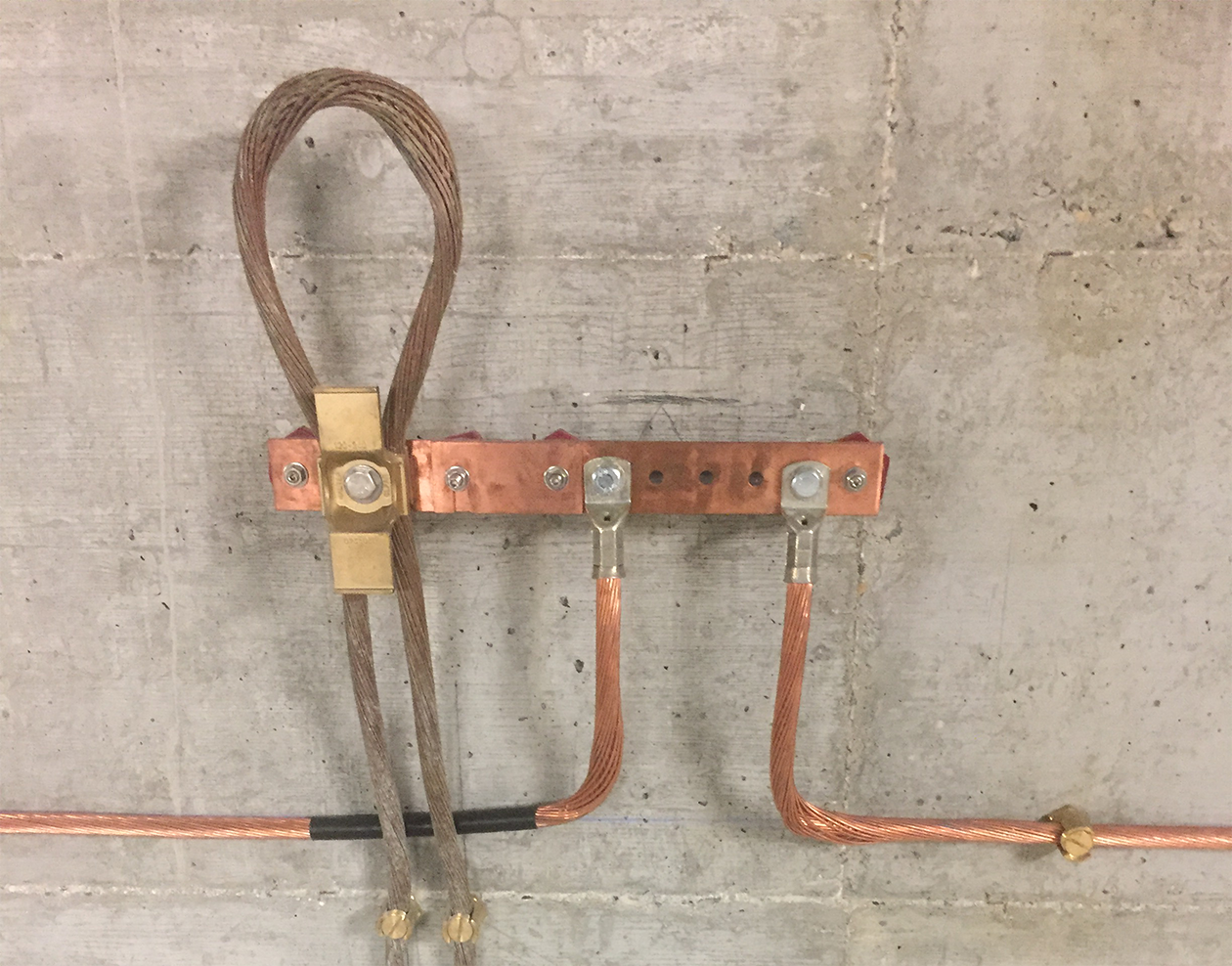

Cable holders are usually used for grounding and equipotential bonding of metal trunking. According to IEC 61000-5-2: Electromagnetic compatibility - Installation and mitigation guidelines - Earthing and cabling; LV cables are installed in a metal trunking (possibly with metal covers) commonly known as cable tray, the latter, through the clamps, is connected to the earth and serves to:

Depending on the nature of the material in contact with the wire clamp, the addition of bimetallic plates or washers may be necessary. Bimetallic plates and washers made of copper and aluminum are used to reduce galvanic corrosion between metal parts of different nature inducing the corrosion phenomenon. The contact between steel/copper, aluminum/copper or zinc/copper generates an electrochemical couple leading to electrolytic corrosion. The bimetallic plates or washers mounted between the clamps have the role of reducing this phenomena while ensuring electrical continuity.

MALTEP offers an extensive range of cable holders for bare copper cables ranging from 25 to 300mm². Our standard range consists of a brass clamp body, however depending on the application MALTEP can offer different surface finishes, such as tinned cable holders, but also different materials such as stainless steel 316 (A4) or aluminium. Our clamps can be offered directly pre-equipped with studs and bimetallic washers. In some cases, for example, for wall mounting of grounding cable, MALTEP can offer you specific assemblies such as cable holders mounted on dowel screw and plastic plugs.

Data sheet

Download

our e-commerce platform is now open to Belgium, Luxembourg, Germany, and Italy

Protect your welding equipment from handling and storage incidents and make it easy to store.