Principle and application

Discover the purpose of earth braids

Function of the earth braids

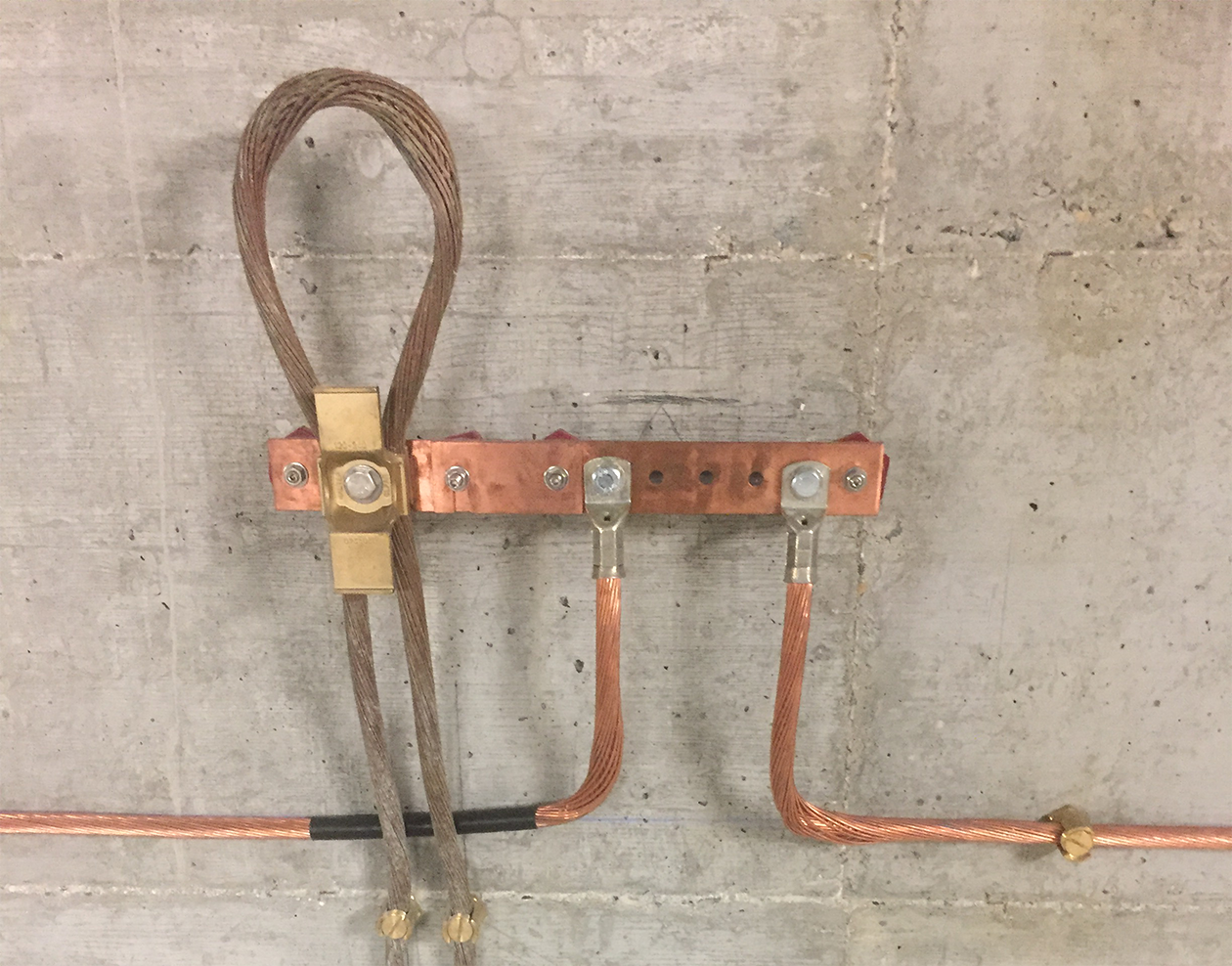

Tinned copper earth braid is used to connect metal structures: frames, racks, electrical cabinets and machines, in order to create the conditions required to ensure equipotentiality of the installations

The mechanical structure of the braid provides flexibility and tensile strength, and permits optimum placement by means of a bolted connection. Copper is used to ensure excellent electrical conductivity, while tin-plating ensures good resistance to oxidation.

Earth braids are used in substations and other electrical installations, as well as in industrial piping.

Definition of the admissible current of the braids

Industrial piping systems

Discover a specific application

Earth braids for the protection of pipes

Flexible tinned copper earth braids are often used to protect people and piping systems by connecting flanges together, as they provide electrical continuity.

As a manufacturer, MALTEP can produce custom flexible earthing braids that meet this type of application. Our braid is made of a small diameter copper wire (0.15 to 0.20 mm) and offers very low impedance and flexibility, making it easy to install.

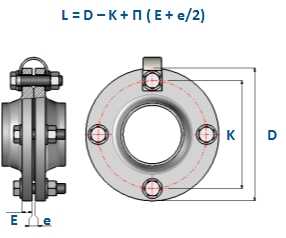

Estimation of the length of a earth braid

- L : Lengths between centres (mm)

- D : Flange diameter (mm)

- K : Diameter at the center of the bolts (mm)

- E : Thickness of the flange (mm)

- e : Thickness of the flange gasket (mm)

Products range

Discover our product range

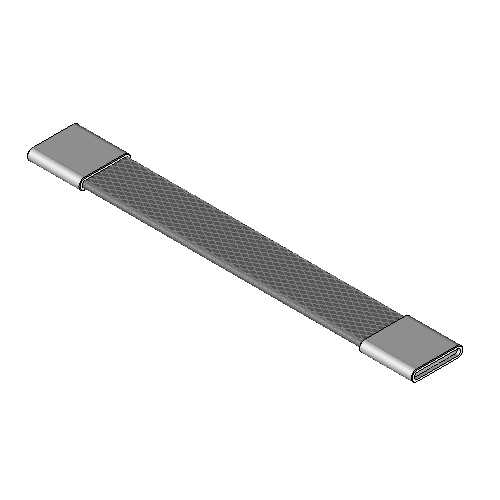

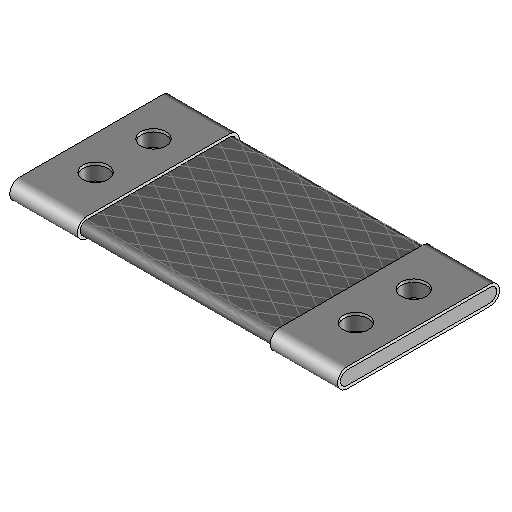

MALTEP standard product range

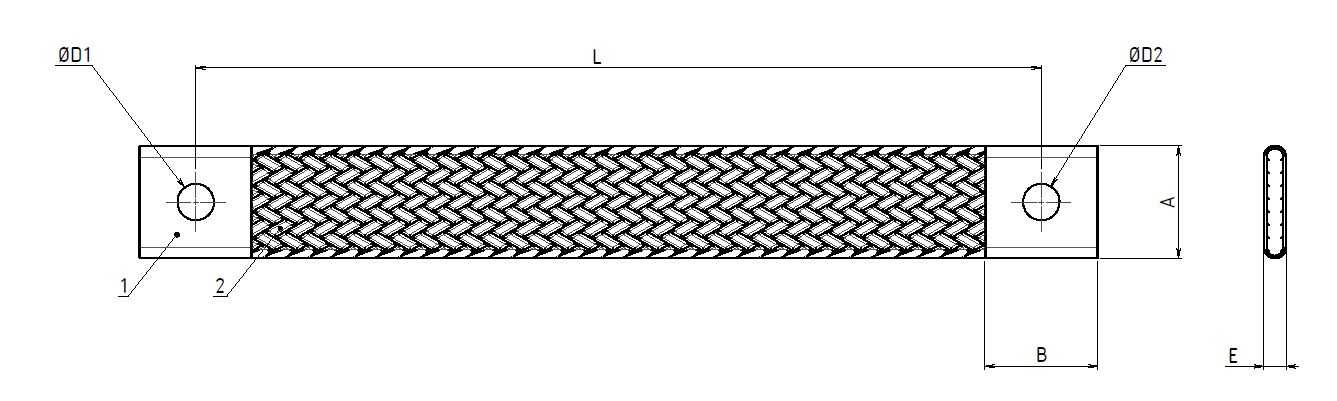

Available at MALTEP in different lengths and cross-sections, as well as in several spacing and terminal diameters, the tinned copper ground braids can also be made to measure. MALTEP also offers ground braids with round lugs, manufacturing on drawings, etc...

Custom earth braids

Discover our manufacturing capacities

Discover our online earth braid configurator

MALTEP can manufacture, for you and with the shortest leadtime, copper earth braids from 6mm² to 240mm² and more. For that, two ways to proceed:

- Use our online earth braid configurator

- Tell us your characteristics

For any quote request, please specify, in the absence of a plan :

• The type of braid (flat braid or round braid)

• The required cross-section

• The length between axes (L)

• The quantity for each type

• The bolt diameter or the hole diameter at each end (D1 and D2)

Correspondence between bolts and hole diameter

| Correspondence Bolts / Hole diameter (mm) | |

| M5 | 5.3 |

| M6 | 6.5 |

| M8 | 8.5 |

| M10 | 10.5 |

| M12 | 13 |

| M14 | 15 |

| M16 | 17 |

| M18 | 19 |

| M20 | 21 |

| M22 | 23 |

| M24 | 25 |

| M27 | 19 |

| M30 | 32 |

| M33 | 35 |

| M36 | 39 |