Discover

Equipotential bonding bars

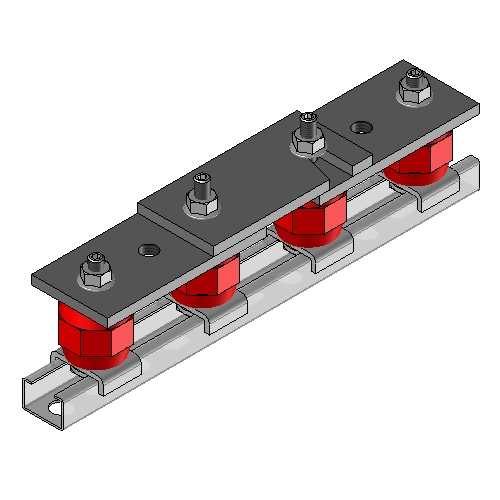

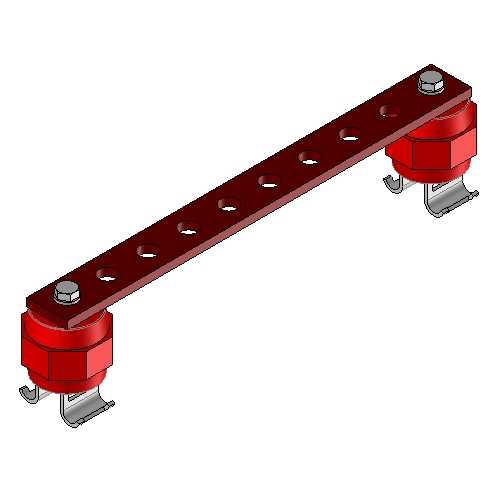

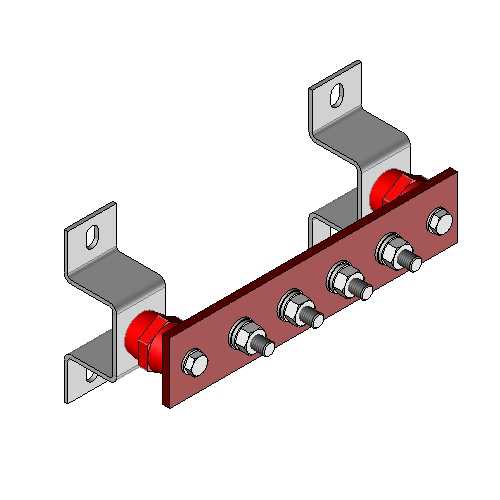

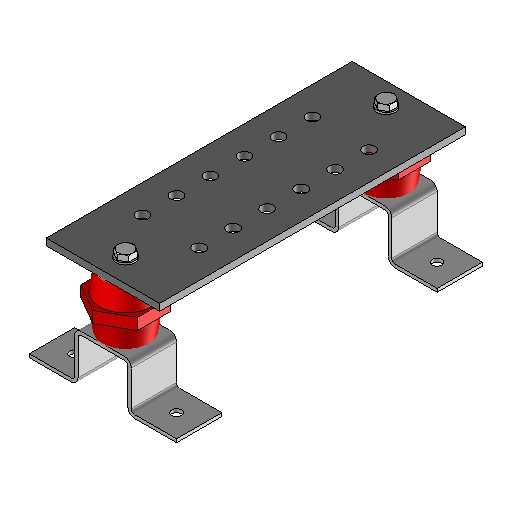

Discover our new models with integrated wall-mounted insulators, for a quick and easy installation!

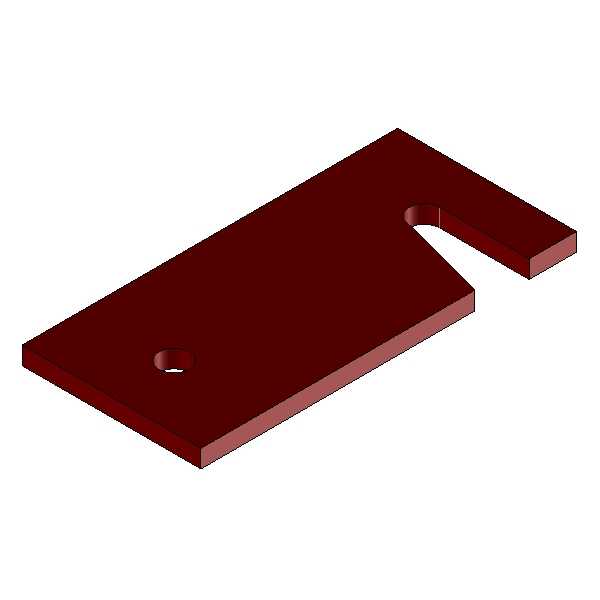

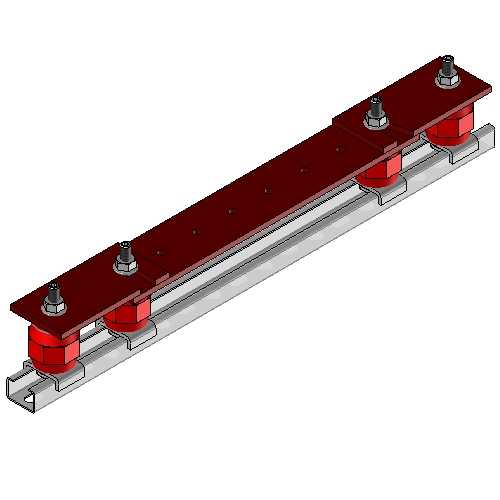

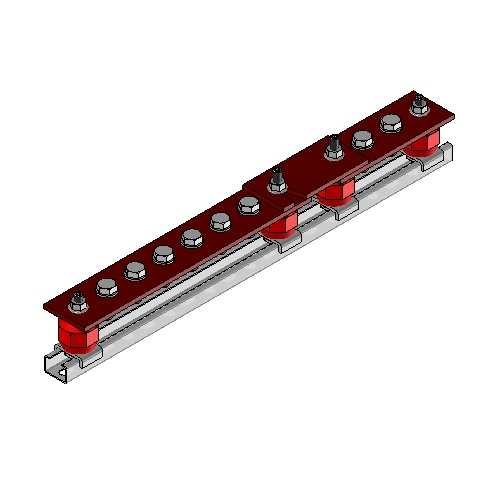

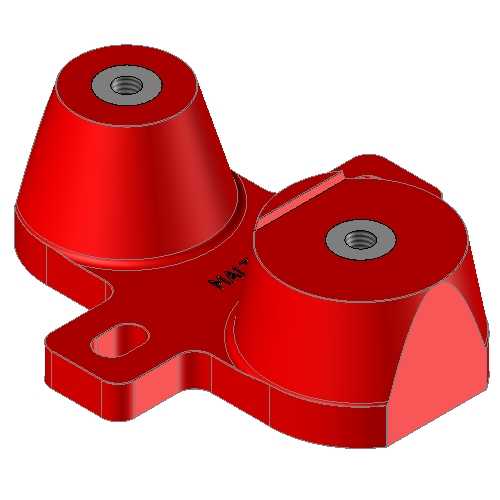

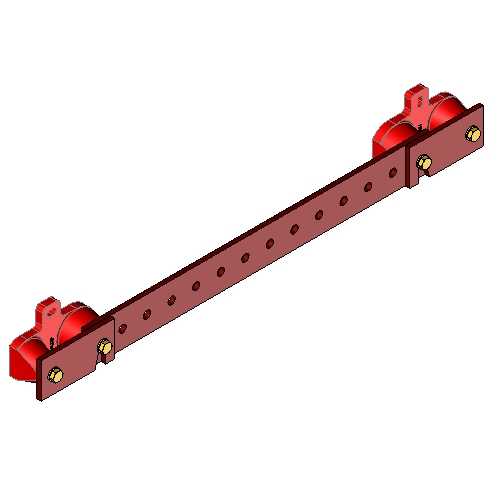

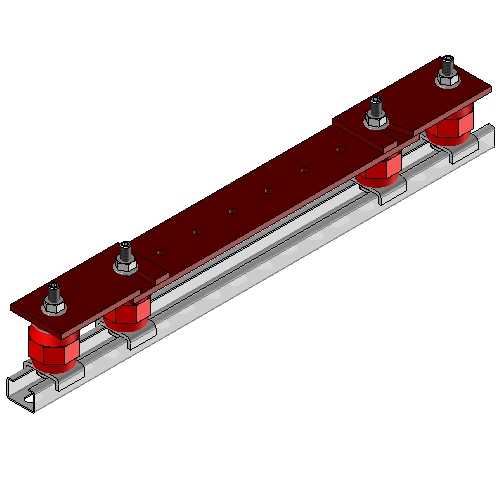

The standards MALTEP model

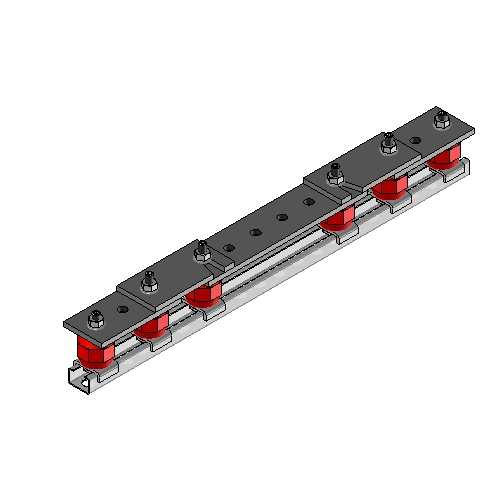

Discover the most common MALTEP models

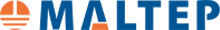

Purpose of the equipotential bonding bar

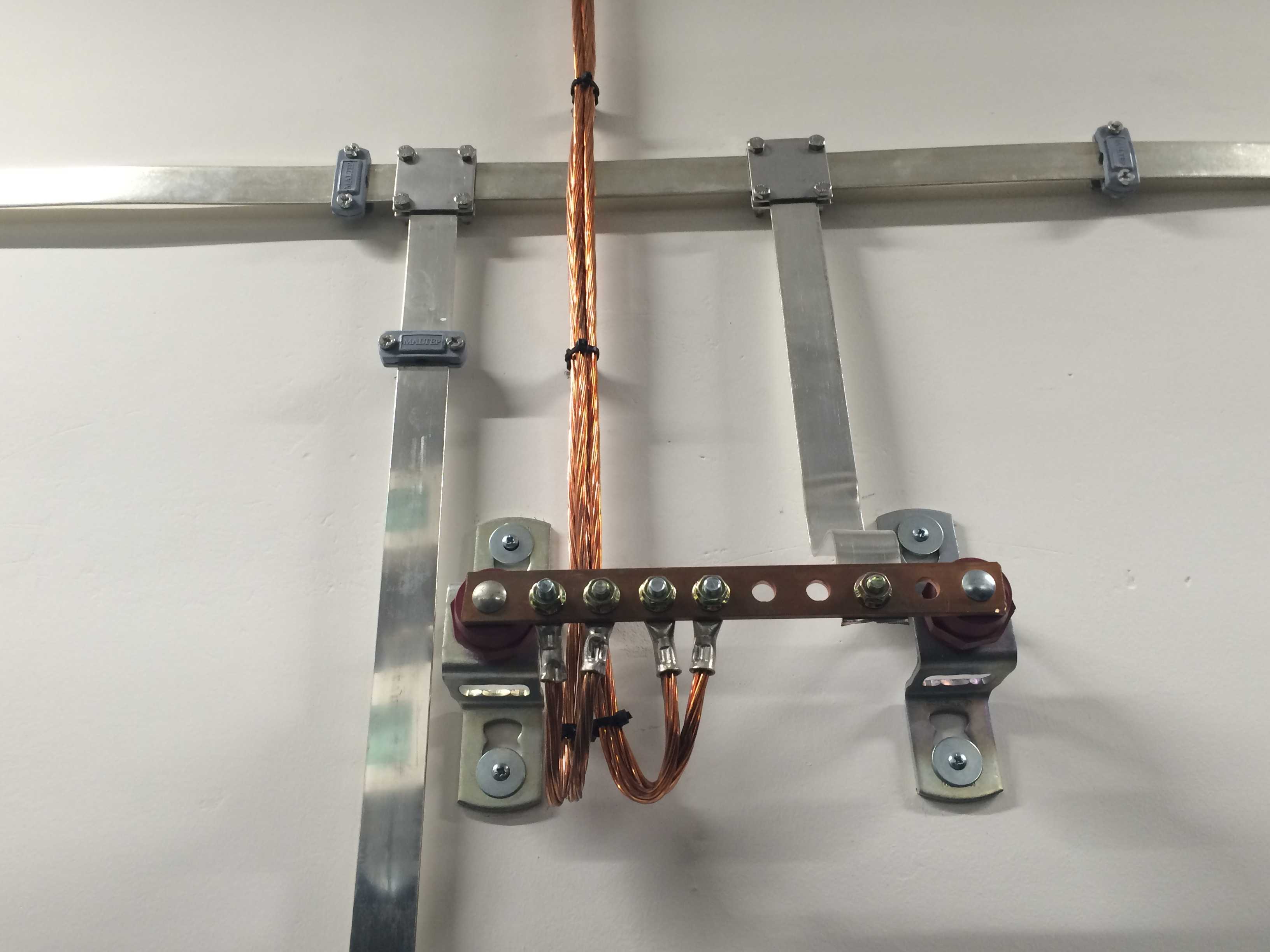

The Equipotential bonding bars are frequently used in medium and low voltage applications. They are used for the interconnection of different earthing circuits or electrical grounds within an electrical installation. The network thus created is then brought to a common potential.

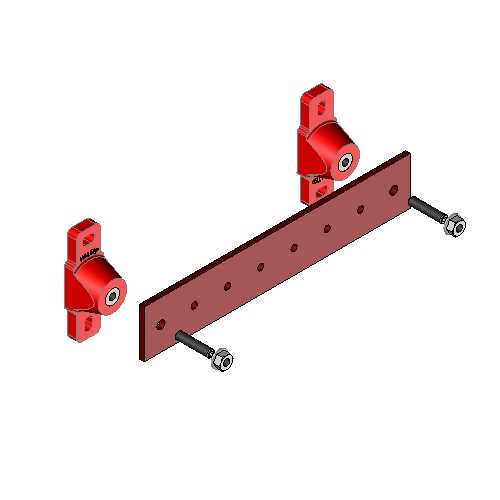

Components nomenclature

The equipotential bonding bars are usually proposed with the following equipment :

- A bare or tinned and perforated bar for connections to ground circuits

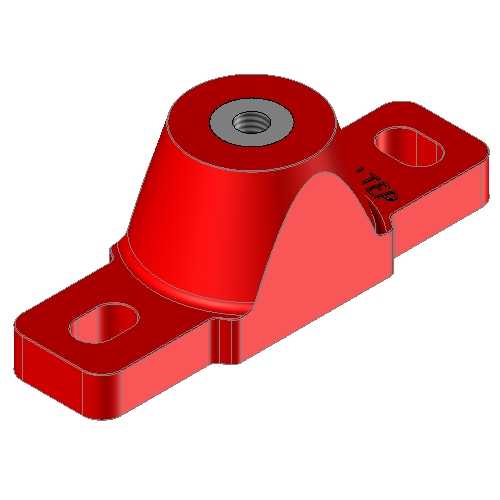

- Low voltage insulators

- A connection means to the support on which the equipotential bonding bar will be mounted

- A disconnecting link for separating the grounding circuit during periodic checks of the grounding resistance

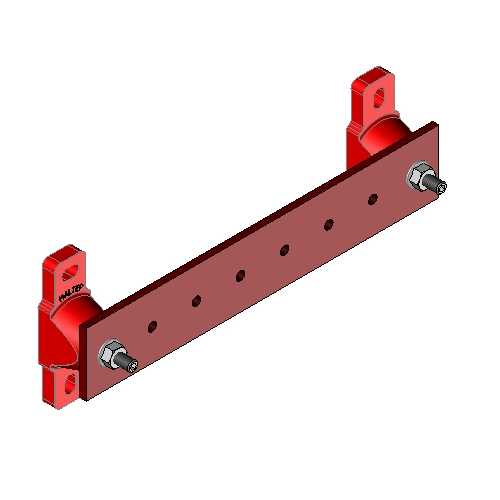

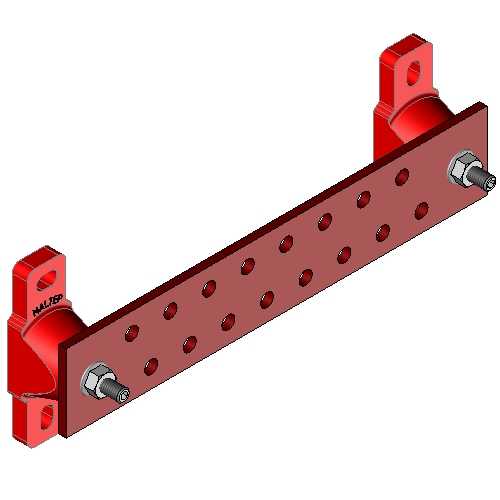

Different models available

The different models shown below are manufactured by MALTEP and are representative of the most common products.

The MALTEP Concept

Discover the MALTEP benefits

The disadvantages of traditional equipotential bonding bars

Although functional, the many designs currently available have some disadvantages:

- Need to dismantle the rail in order to correctly adjust the equipotential bar on its support

- Overall dimensions of the mounting rail and bar assembly

The MALTEP solution

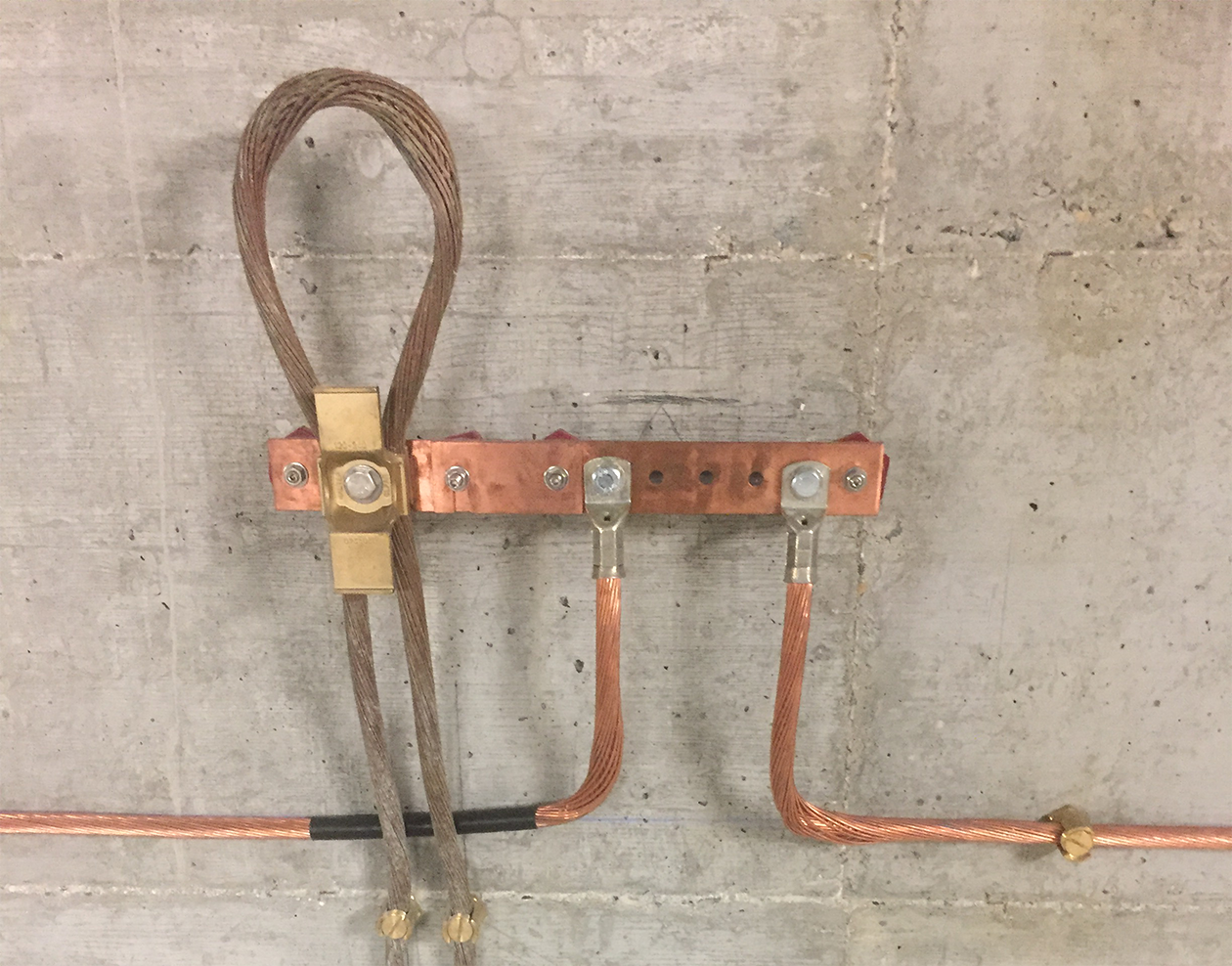

In an effort to continously bring innovative solutions and ease the installation of these products, MALTEP has developed a new generation of equipotential bars integrating both the conductor insulation and its fastening.

With the new MALTEP insulators, Patent N°EP 20305105.7, the new generation of equipotential bars offer you:

- DIRECT MOUNTING without dismantling the copper bar

- BETTER STABILITY thanks to built-in fastening insulators with a total of 4 points of fixation

- BETTER RESISTANCE to tearing

- CLUTTER REDUCTION with a smaller product height

- Significant WEIGHT reduction

- POSITIONING facilitated by oblong holes

Characteristics

Discover our technical characteristics

Characteristics of our standard equipotential bonding bars and galvanized rails

| Commercial ref | Product ID | Cross-Section (mm) | Length (mm) | Free holes | Holes Dia. (mm) | Length between axis (mm) | Weight (Kg) |

| Equipotential bonding bars without disconnecting link | |||||||

| BET6 | 287284 | 50x5 | 280 | 6 | 6.5 | 25 | 1.25 |

| BET10 | 245366 | 50x5 | 420 | 10 | 6.5 | 25 | 1.75 |

| BET15 | 245367 | 50x5 | 595 | 15 | 6.5 | 25 | 2.25 |

| BET20 | 245368 | 50x5 | 770 | 20 | 6.5 | 25 | 2.80 |

| BET25 | 245370 | 50x5 | 945 | 25 | 6.5 | 25 | 3.35 |

| Equipotential bonding bars with disconnecting link | |||||||

| BETC6 | 245376 | 50x5 | 350 | 6 | 6.5 | 25 | 1.65 |

| BETC10 | 245371 | 50x5 | 490 | 10 | 6.5 | 25 | 2.15 |

| BETC15 | 245373 | 50x5 | 665 | 15 | 6.5 | 25 | 2.65 |

| BETC20 | 245374 | 50x5 | 840 | 20 | 6.5 | 25 | 3.20 |

| BETC25 | 245375 | 50x5 | 1015 | 25 | 6.5 | 25 | 3.75 |

| Disconnecting link only | |||||||

| BTC | 245397 | 50x5 | 105 | – | – | – | 0.70 |

Characteristics of our equipotential bonding bars with integrated wall suports

| Commercial ref | Product ID | Cross-section (mm) | Length (mm) | Free holes | Hole dia. (mm) | Length between axis (mm) | Weight (Kg) |

| Equipotential bonding bars without disconnecting link | |||||||

| BEQ6 | 306316 | 50x5 | 295 | 6 | 6.5 | 25 | 0.86 |

| BEQ10 | 306317 | 50x5 | 420 | 10 | 6.5 | 25 | 1.17 |

| BEQ15 | 306318 | 50x5 | 595 | 15 | 6.5 | 25 | 1.55 |

| BEQ20 | 306319 | 50x5 | 770 | 20 | 6.5 | 25 | 1.93 |

| BEQ25 | 306320 | 50x5 | 945 | 25 | 6.5 | 25 | 2.32 |

| Equipotential bonding bars with disconnecting link | |||||||

| BEQC6 | 306853 | 50x5 | 350 | 6 | 6.5 | 25 | 1.28 |

| BEQC10 | 306854 | 50x5 | 490 | 10 | 6.5 | 25 | 1.59 |

| BEQC15 | 306855 | 50x5 | 665 | 15 | 6.5 | 25 | 1.97 |

| BEQC20 | 306856 | 50x5 | 840 | 20 | 6.5 | 25 | 2.35 |

| BEQC25 | 306857 | 50x5 | 1015 | 25 | 6.5 | 25 | 2.73 |

| Disconnecting link only | |||||||

| BQC | 306858 | 50x5 | 105 | – | – | – | 0.56 |

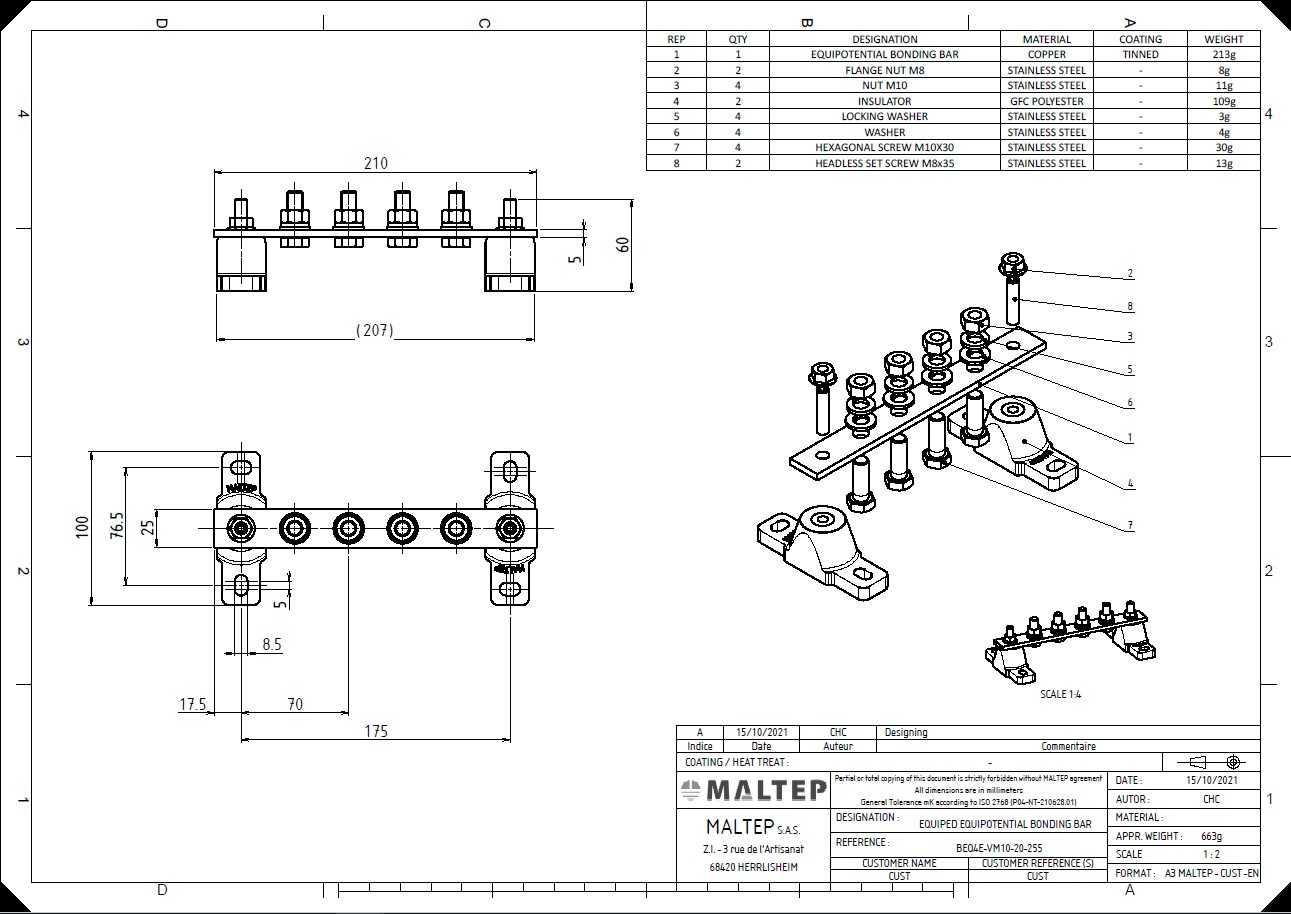

Customized equipotential bonding bars

Manufacturing of custom bars

Manufacturing of on demand equipotential bonding bars

Despite a wide range of equipotential bonding bars , you can't find the version you need for your project! Contact us, MALTEP will manufacture the bar that suits your needs.

Don't forget to tell us :

- Nature of the conductor

- Cross section of the conductor

- Number of free holes

- Diameter of free holes

- Length between axis of the free holes

- With or without disconnecting link

- A drawing if possible