Discover

Earth rods

Discover our earth rods, their characteristics and specificities, the means of connection to your earthing network

Ground connections and soil's resistivity

The importance of grounding and soil resistivity

Understanding the importance of ground connection and resistivity of soils

Earth rods are essential elements in the realization of durable, low-resistance (underground) grounding systems. Their main advantage over other types of grounding electrodes such as grounding grids or buried conductors is that they allow to reach the deep layers of the ground, which are often more conductive than the surface layers. As a reminder, the resistance of an earth electrode depends essentially on :

- It's dimension

- It's shape

- It's soil's resistivity in which it is established

This varies according to the nature of the soil, but also the humidity level and the temperature (which varies according to the season). And if the soil is not homogeneous, it can also vary according to the depth. For example, the geological layers of the subsoil through which water flows are not suitable for the establishment of ground connections because they have very permeable stony zones, washed out by water purified by natural filtration, and presenting high resistivity. It may therefore be necessary to cross these layers with earth rods in order to find conductive zones and therefore more favorable to the installation of a high-performance and durable earth connection.

In practice, the resistivity of a soil increases when the humidity level decreases. The geological layers of the subsoil through which water flows are not suitable for the establishment of ground connections because they have very permeable stony areas, washed by water purified by natural filtration and with high resistivity.

It is therefore necessary to cross the geological layers with earth rods in order to find conductive zones and therefore more favorable to the installation of a permanent earth connection.

Understand the importance of earth rods as earthing elements

Depending on the nature of the soil in which it is installed, the rod, as an earth electrode, will promote the dissipation of the fault current in the soil, both in a lightning protection and grounding installation. When it is necessary to use multiple earth rods, they are usually arranged in a crow's foot, triangular, or line pattern.

Soil resistivity values

TO KNOW

The resistivity values in the following table are given, for information purposes, for a certain type of soil:

| Soil resistivity | ||||||||

| Nature of the ground | Resistivity (Ω.m) | |||||||

| Wetlands | Below 30 | |||||||

| Silt | 20 - 100 | |||||||

| Humus | 10 - 150 | |||||||

| Moist peat | 5 - 100 | |||||||

| Plastic clay | 50 | |||||||

| Marls and compact clays | 100 - 200 | |||||||

| Jurassic marl | 30 - 40 | |||||||

| Clayey sand | 50 - 500 | |||||||

| Siliceous sand | 200 - 3 000 | |||||||

| Bare stony ground | 1 500 - 3 000 | |||||||

| Stone floor covered with grass | 300 - 500 | |||||||

| Soft limestone | 100 - 300 | |||||||

| Compact limestone | 1 000 - 5 000 | |||||||

| Cracked limestone | 500 - 1 000 | |||||||

| Shale | 50 - 300 | |||||||

| Micaschists | 800 | |||||||

| Granite and sandstone according to alteration | 1 500 - 10 000 | |||||||

| Very altered granites and sandstones | 100 - 600 | |||||||

In order to approximate the resistance of a earth connection, the following average values can be used:/span>

| Soil resistivity | ||||||||

| Nature of the ground | Resistivity's average value (Ω.m) | |||||||

| Oily arable land, wet compact fills | 50 | |||||||

| Lean arable land, gravel, coarse fill | 500 | |||||||

| Bare stony soils, dry sand, impermeable rocks | 3 000 | |||||||

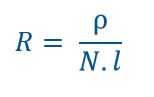

Estimation of the earth resistance

It is possible to determine, in an approximate way, the ground resistance, valid for a homogeneous ground:

- R : Earth resistance (Ω)

- ρ : Soil resistivity (Ω.m)

- N : Number of earth rods

- l : Length of earth rod (m)

TO KNOW

The equation is valid only if the individual earth rods are spaced at a distance greater than 4 x l.

Selecting the earth rod

Discover the characteristics of earth rods

Earth rods characteristics

MALTEP offers a complete range of earth rods according to different selection criteria:

- Material

- Dimensions (diameter and length)

- Means of extension

The resistance of the ground depends mainly on the length of the installed rods and their number. Contrary to popular belief, the diameter has very little influence on the resistance value, as does the material, since the metals used in the manufacture of the rods (copper, steel, etc.) have a much higher conductivity than the soil. When it is difficult to reach the desired resistance of the ground, it is therefore preferable to increase the length of the earth rods, if the nature of the soil allows it, to try to reach more conductive layers at depth, then multiply the number of earth rods if the soil is too hard at depth.

Earth rods material

As standard, MALTEP earth rods are offered as described below:

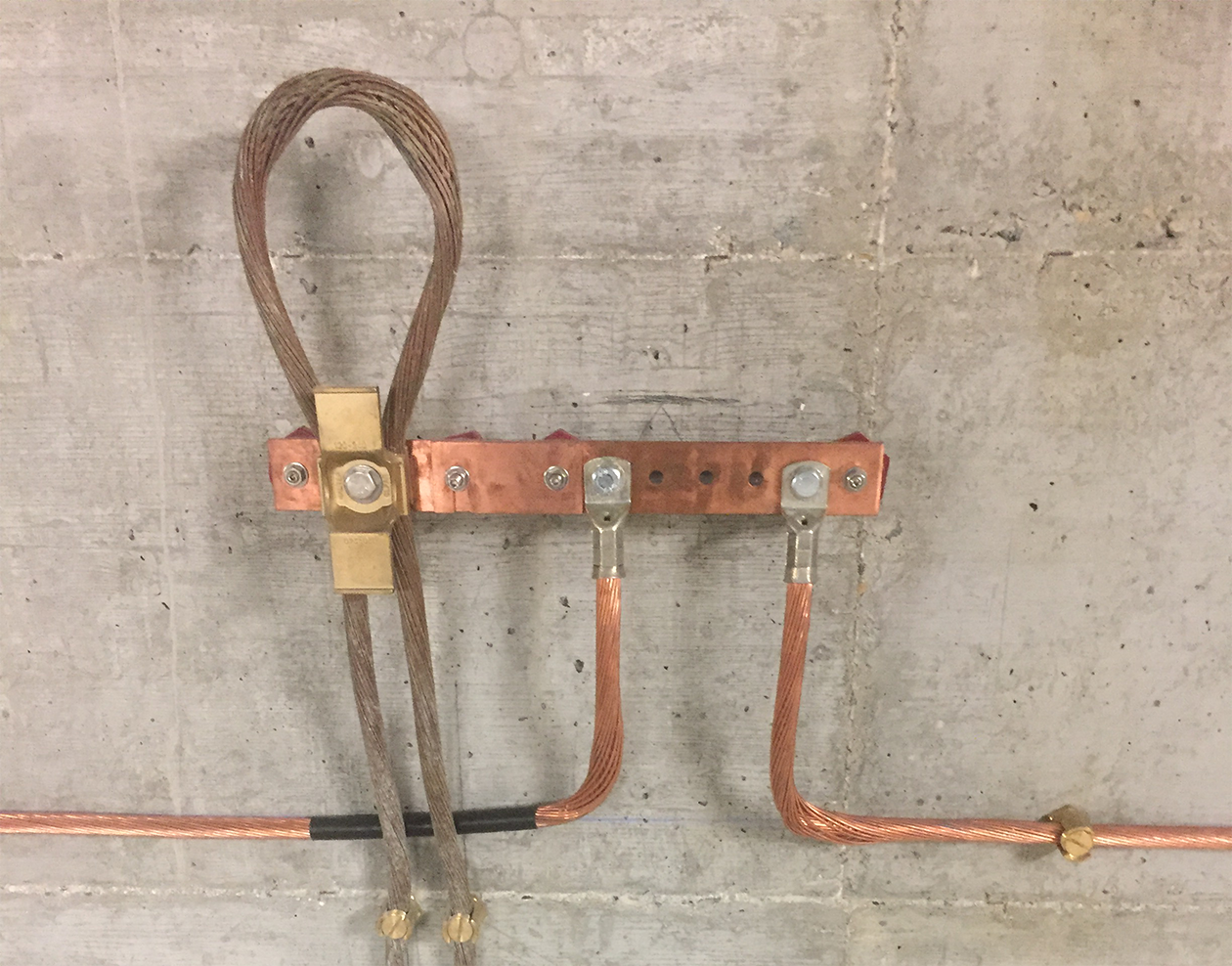

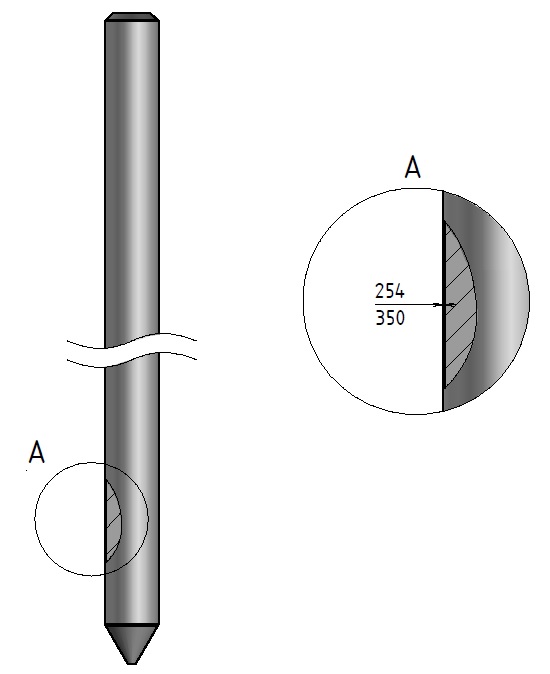

The copper bonded steel earth rods are manufactured from a steel core which is placed in an electrolytic bath in order to deposit the required thickness of copper by electrolysis. The purity of the deposited copper is 99.9%. Several thicknesses of copper plating are offered:

- Minimum thickness of 254µm

- Average thickness of 350µm

The electrolytic coating promotes the longevity of copper-bonded steel earth rod for a long-lasting and durable installation.

Stainless steel earth rods are offered in the following grades:

- Z33 C13 stainless steel

- 316 (A4) stainless steel

Stainless steel earth rods are preferred for soils with high corrosion characteristics.

TO KNOW

Upon request, MALTEP can also offer you grounding rods in galvanized steel and all copper.

The galvanized steel earth rod can be considered for use in terrains with non-aggressive characteristics

The full copper earth rod is, by nature, very conductive and has a very good resistance to corrosion, it can be considered for use on land with aggressive characteristics.

Understanding the diameters of copper-bonded earth rods

In the earthing industry, the diameters of copper-bonded earth rods are traditionally expressed as 5/8” or 3/4”.

However, these values do not represent the actual diameter of the rod; they actually correspond to the nominal thread size:

- A 5/8” ( T = 16 mm) rod has a real diameter of D = 14.2 mm.

- A 3/4” (T = 19 mm) rod has a real diameter of D = 17.2 mm.

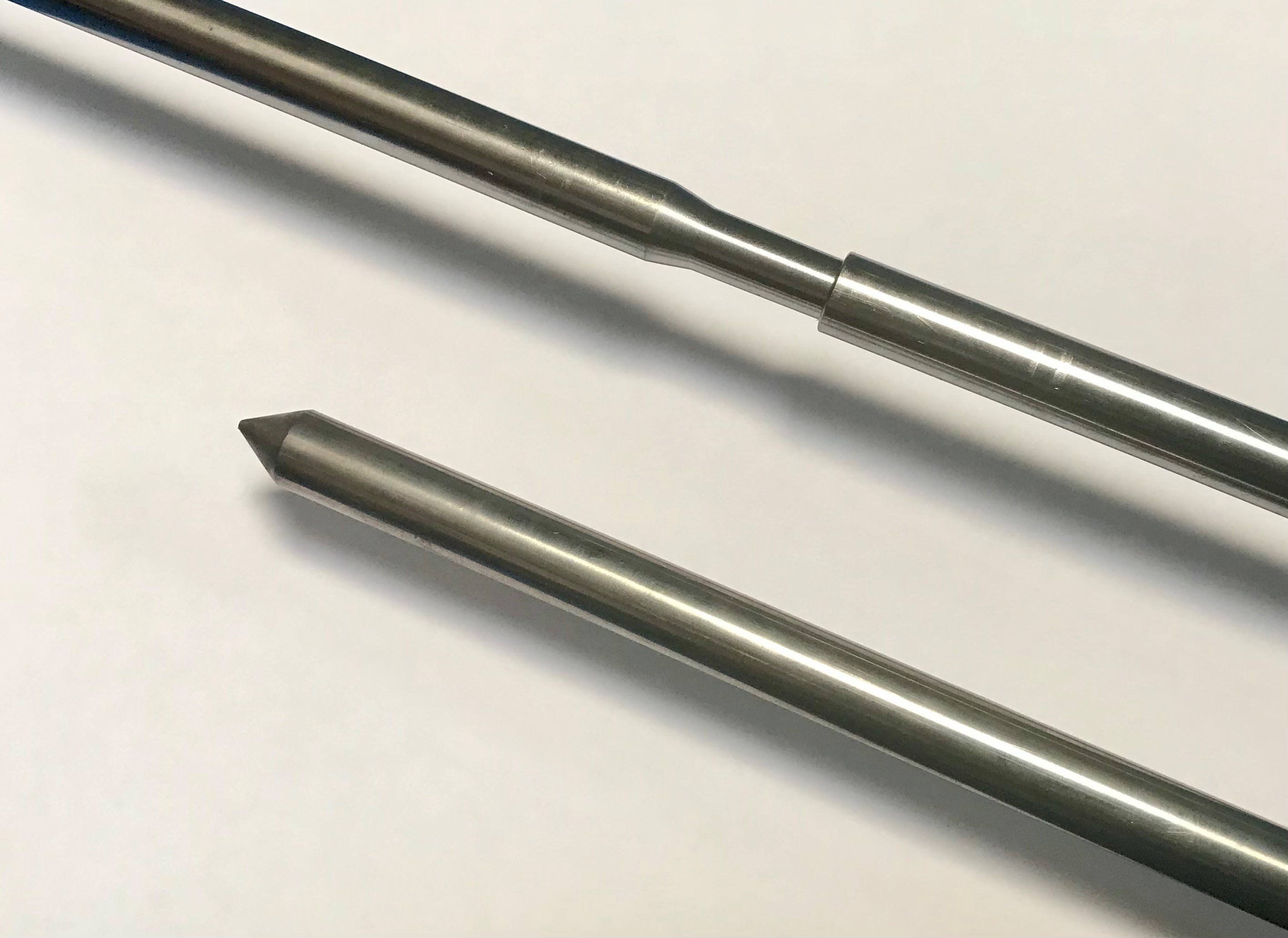

Understanding earth rod extension solutions

There are various ways to extend the length of MALTEP earth rods in order to reach the desired soil layer.

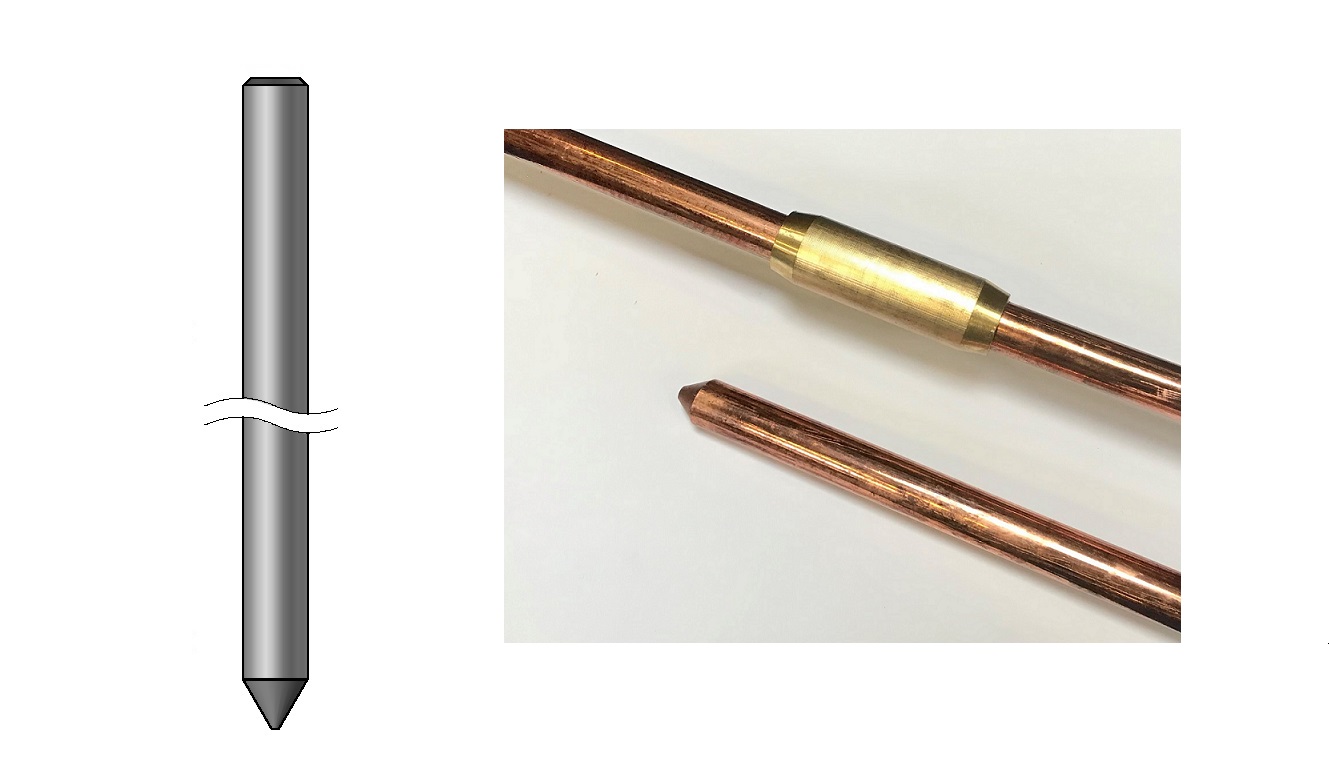

The extension of a non-threaded earth rod can be achieved by using a non-threaded brass coupler.

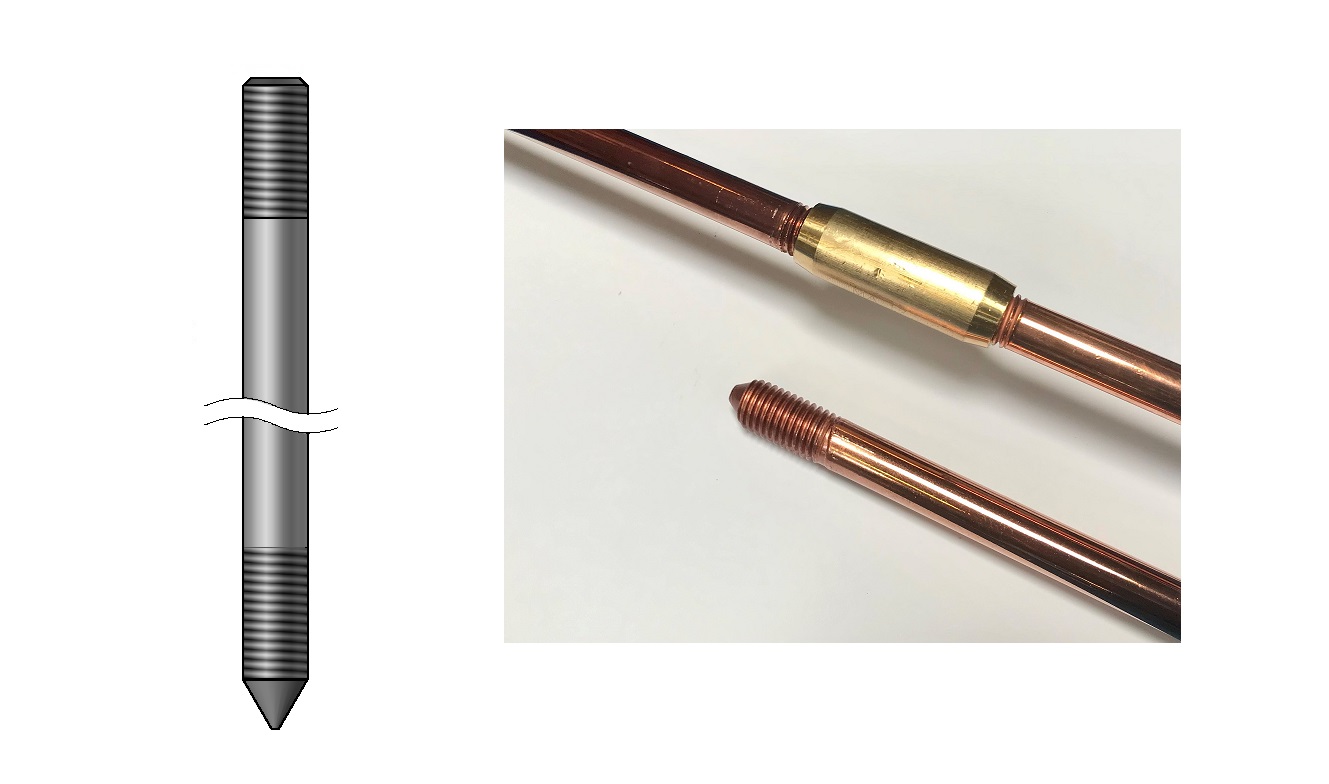

The extension of a threaded earth rod is accomplished by using a threaded coupler of a diameter compatible with the rod.

As its name indicates, the auto-extensible earth rod does not require any additional accessory in order to realize the extension, it is done by driving the earth rod on the previous one already present in the ground.

Overview of MALTEP earth rods product range

Earth rod to conductor connection

Find out how to connect the earth rod to the earthing conductor

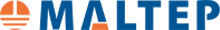

MALTEP solutions for the connection between earth rod and conductor

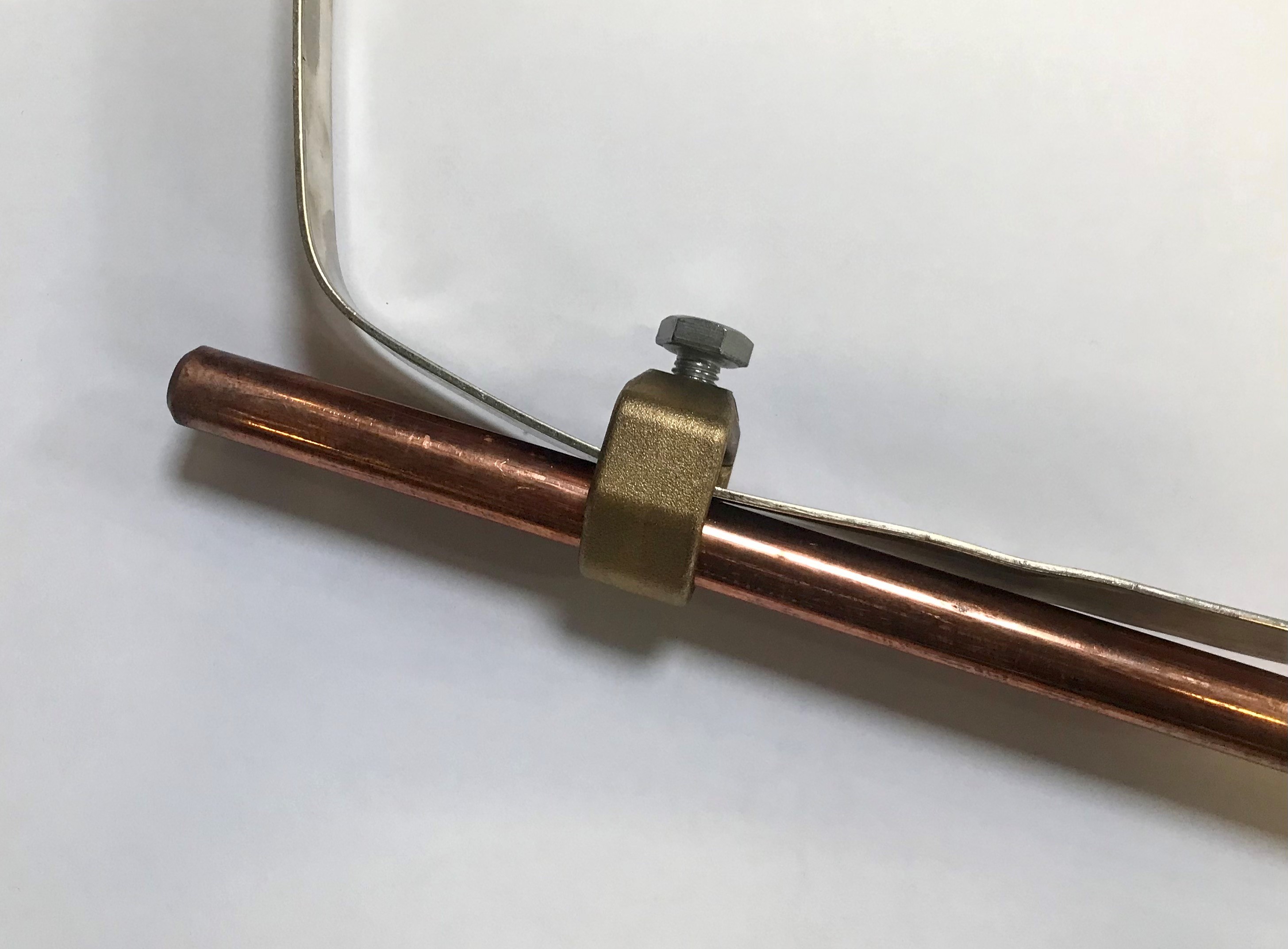

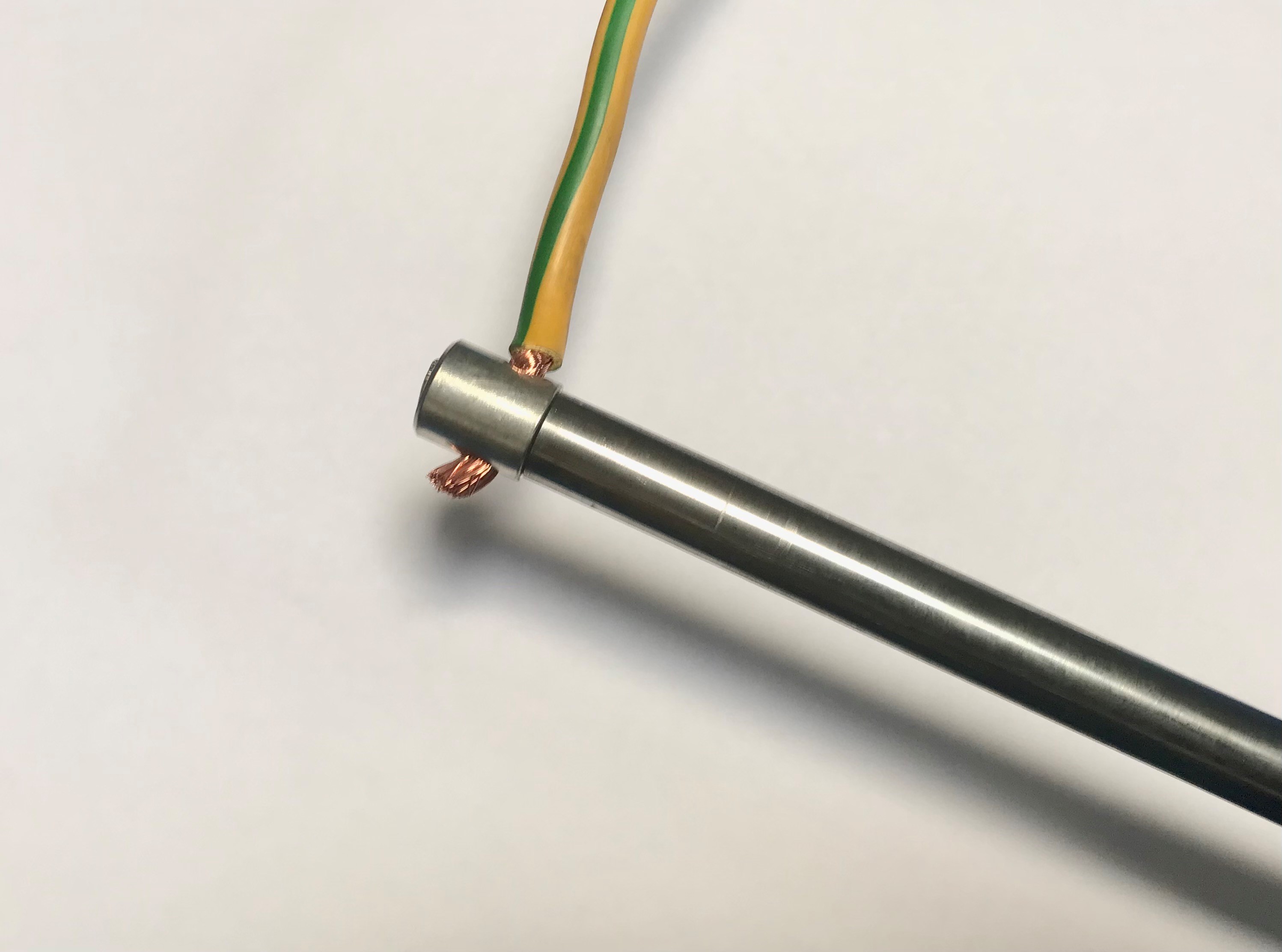

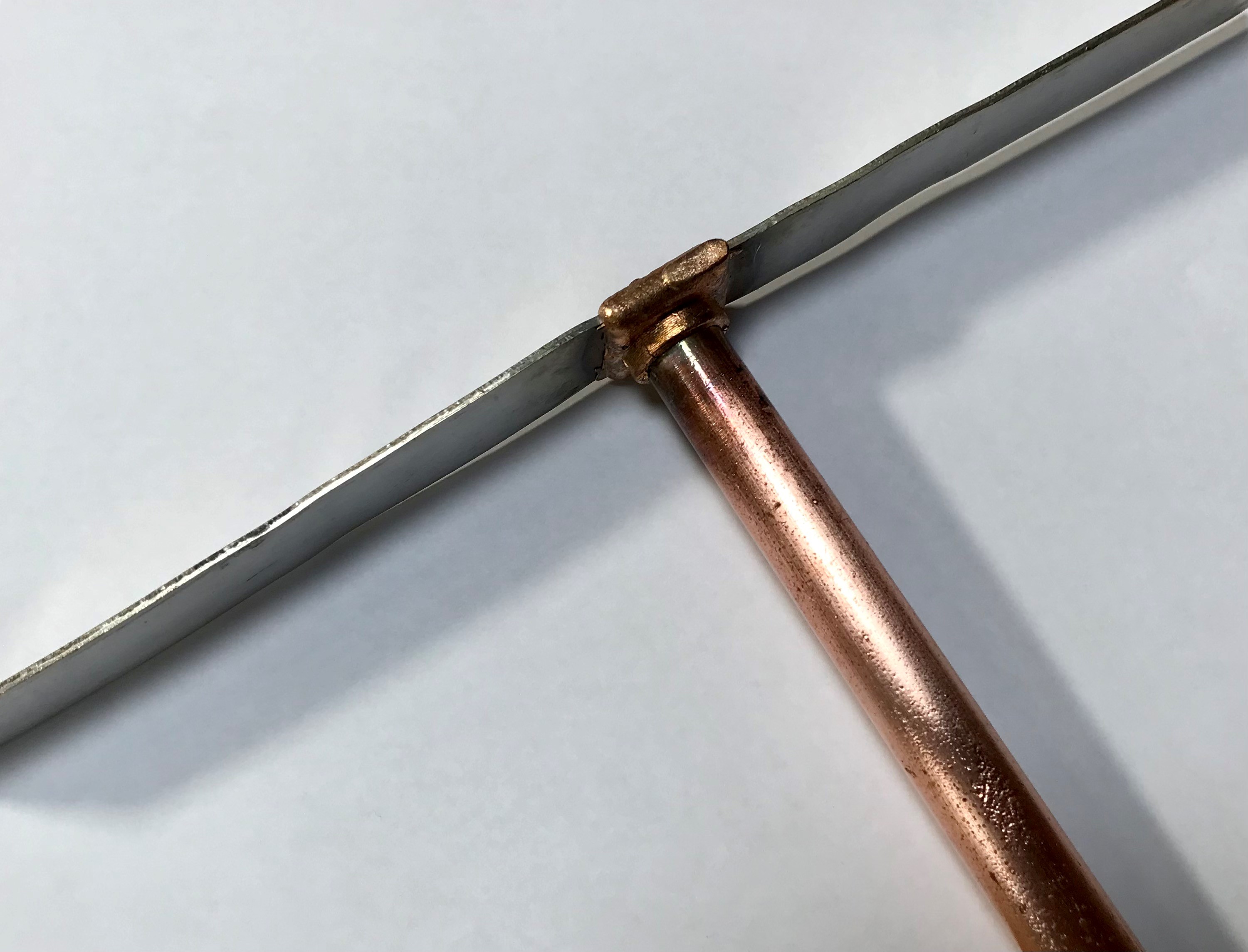

MALTEP offers different ways to connect the earth rod to the earthing conductor which can be of different shapes such as multi-stranded cable, round or tape:

- Mechanical clamps with screwed connections

- Mechanical clamps with knock-in head connections

- Exothermic welding connections

Overview of the range of connections between earth rods and conductors

Mounting the earth rod

Find out basics information

Information on the mounting of earth rods

CLIMATIC INFLUENCES ON THE RESISTIVITY OF A SOIL

Humidity and temperature affect the resistivity of a soil. The resistivity of a soil increases when the humidity level decreases. Therefore, geological layers with water currents are not suitable for grounding.

It is therefore advisable to cross these geological layers with long earth rods in order to reach low resistivity layers

CLIMATIC INFLUENCES ON THE RESISTIVITY OF A SOIL

Where there is a risk of frost or drought, the length of the earth rod must be increased by 1 m or 2 m.

It is possible to reduce the resistance value of the earth connection by placing several vertical rods connected in parallel and separated by at least their length in case of two rods, and more if there are more.

Precautions to take when driving an earth rod into the ground

Driving an earth rod into the ground can present several risks to the operator and to the integrity of the earth rod:

RISK OF MECHANICAL SHOCK

Risk of mechanical shock, especially to the operator's hand when driving the earth rod into the ground

RISK OF ELECTRICAL SHOCK

Risk of electric shock for the operator when driving the earth rod into the ground in contact with a buried and active line

MALTEP offers different accessories for the protection of the operator and earth rod when driving in the ground:

Earth rods product range

Access our full range in a few clics