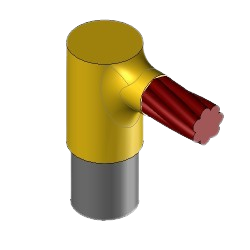

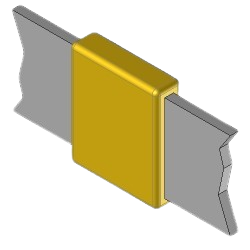

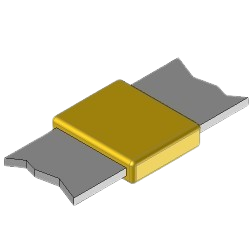

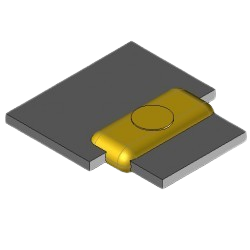

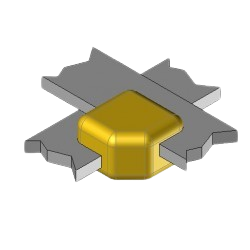

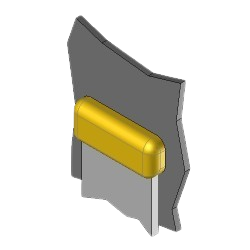

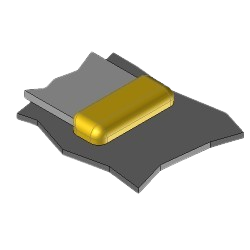

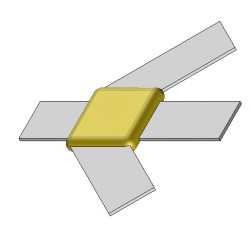

Mold scraper

For the removal of slag present inside the crucible and resulting from the exothermic weld operation

- Reference

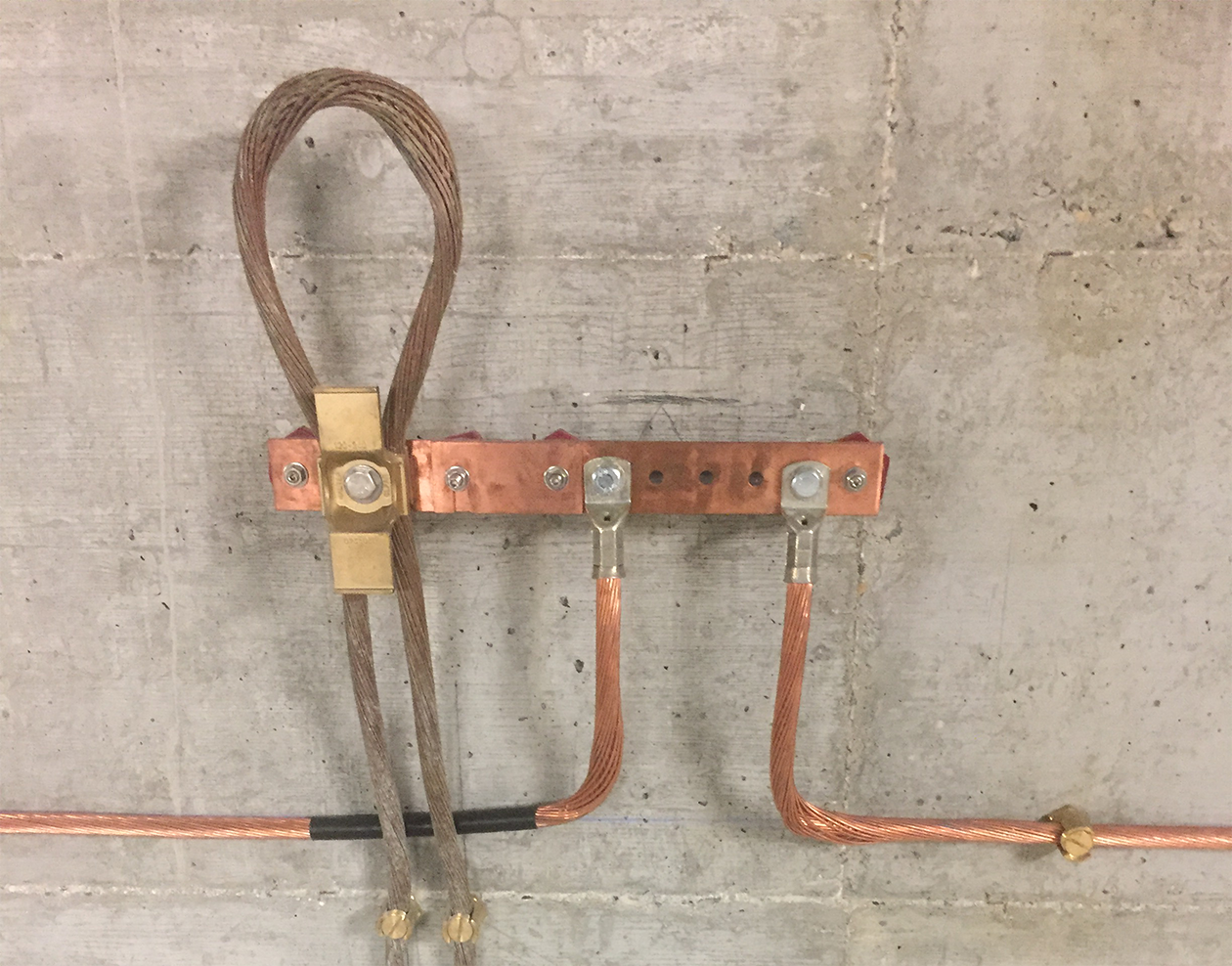

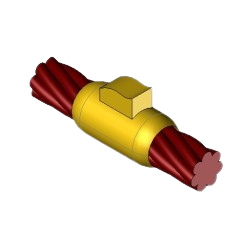

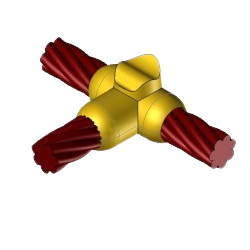

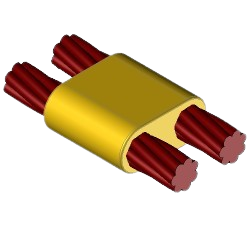

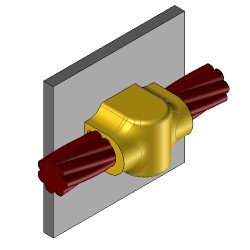

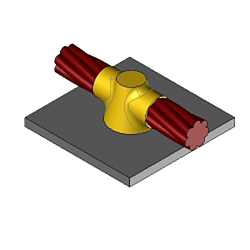

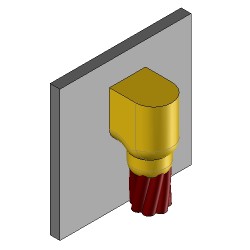

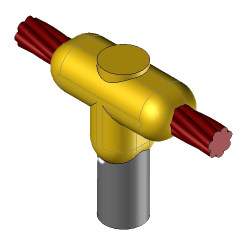

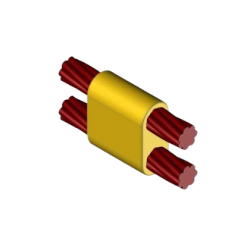

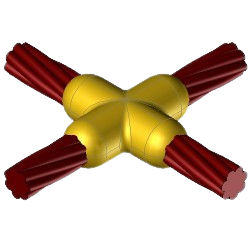

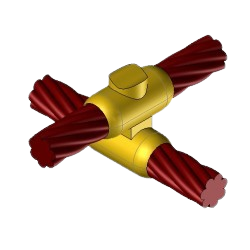

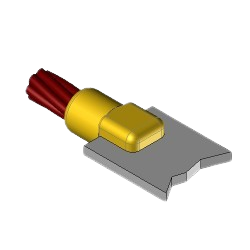

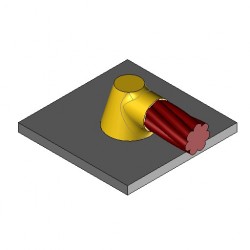

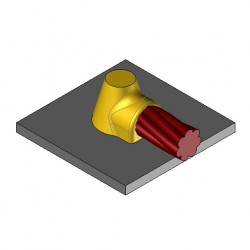

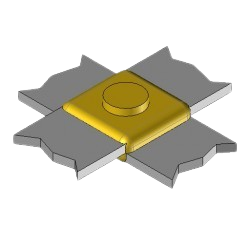

The exothermic welding is a self-sufficient process to achieve high quality electrical connections between copper, copper alloys or steel conductors. The process implies the use of a graphite mold allowing the molten metal present inside to come in contact with the conductors present and to weld them in a definitive way.

During the cleaning stage, le allows to eliminate the slag and welding residues present inside the mold in the crucible as well as in the casting hole. The material of the mold being graphite, carefully the cleaning of the mold during the use of the scraper must be carried out carefully. The cleaning of the mold is done once the conductors are released and the clamp and mold in open position.

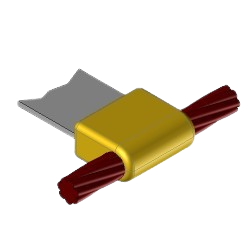

The size of the scraper is calibrated according to the size of the crucible. In order to select the appropriate scraper, it is necessary to know the type of welding powder associated with the mold:

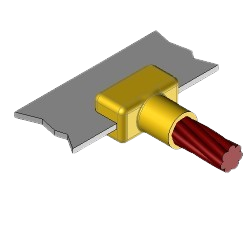

- Scraper of type KG10 for use with metal powder cartridges from KW45 to KW115

- Scraper of type KG12 for use with metal powder cartridges from KW150 to KW250

- Scraper of type KG13 for use with metal powder cartridges ≥ 2xKW150

► How to choose all the required exothermic welding materials ?

To choose all of the required materials, follow the steps below:

- Select the graphite mold

- Select the handle clamp

- Select the metal powder

- Select the ignition method

- Select the accessories and safety equipments

► What if the welding configuration is not available on MALTEP website ?

MALTEP also manufactures graphite molds for the realization of particular welding configuration.

Do not hesitate to consult us for any particular request with the following welding inputs:

• The configuration of the weld: tee, parallel, etc..

• The nature of the conductors to be welded: cable, round, rebar, etc. (note that aluminium is not suitable with exothermic welding)

• The cross section, diameter, conductors dimensions

• The number of welds to be done for each type of weld

► Wants to know more ?

|

|

Discover our exothermic welding overview |

Data sheet

- {0}

Products that you might need

-

Default

⚡ MALTEP Participates in the Senegalese power grid development project ⚡VINCI ENERGIES and SENELEC launched work on the second phase, called Pôle 2026, of the Senegalese electricity network development project

-

Default

⚡ MALTEP participates in the Middle East Energy exhibition in Dubai ⚡As every year, for the last 5 years, MALTEP will be present at the Middle East Energy exhibition in Dubai, United Arab Emirates. We will be there from 16th to 18th of April to present our e [...]