Welding powder

The metal powder provides the required material in order to perform the exothermic welding of the conductors

|

|

Each type of weld requires a specific welding powder cardtridge, make sure you have the right mold, use our selection guide |

- Reference

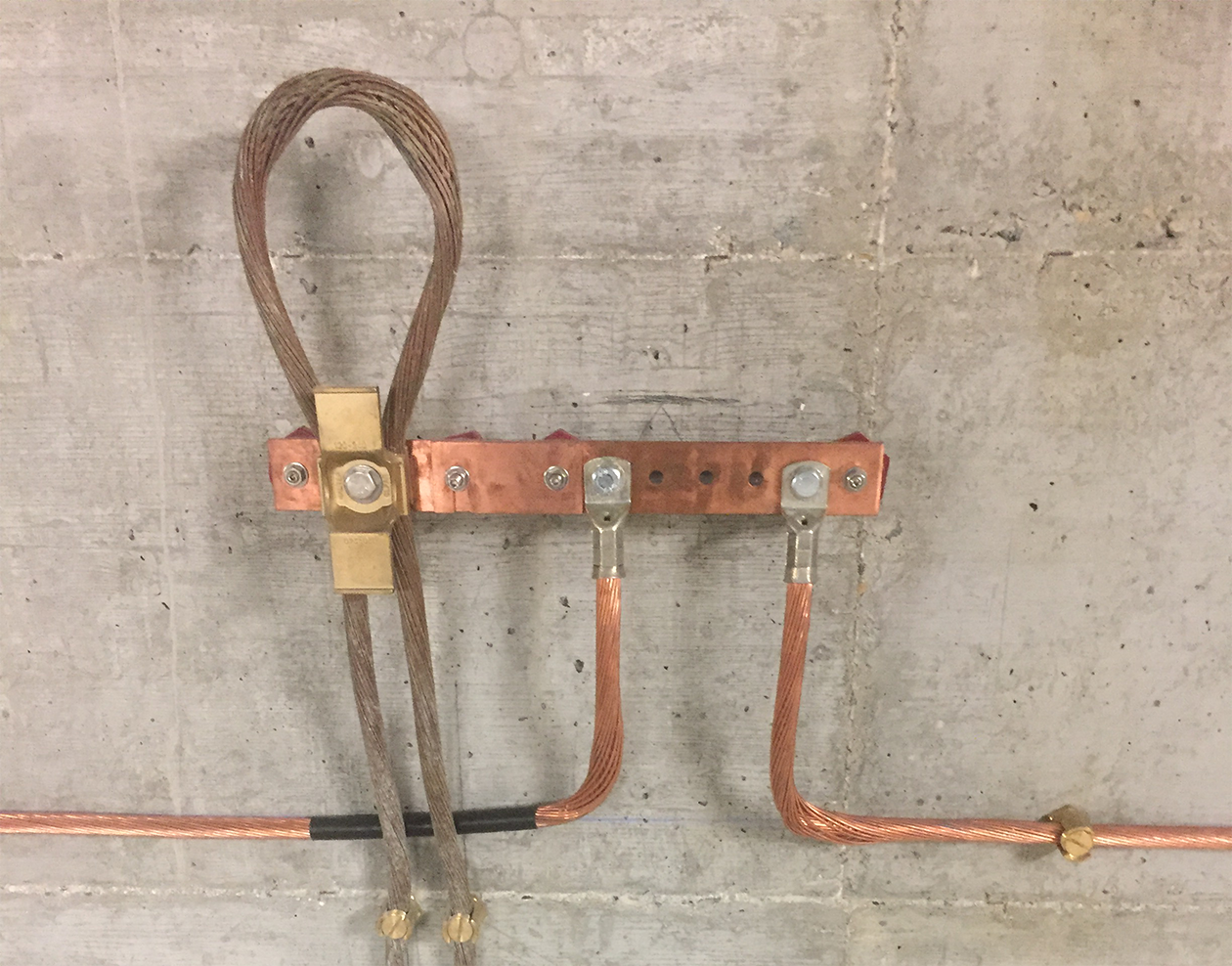

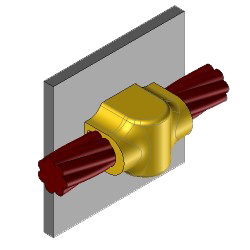

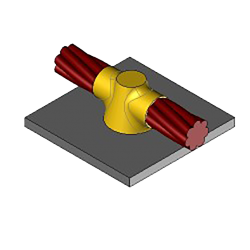

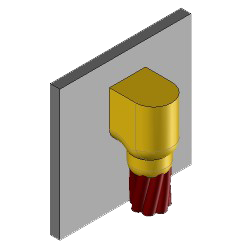

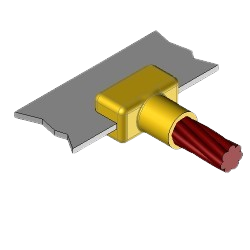

The exothermic welding is a self-sufficient process to achieve high quality electrical connections between copper, copper alloys or steel conductors. The process implies the use of a graphite mold allowing the molten metal present inside to come in contact with the conductors present and to weld them in a definitive way.

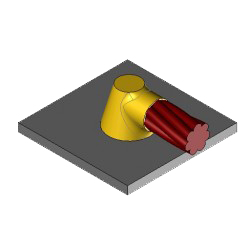

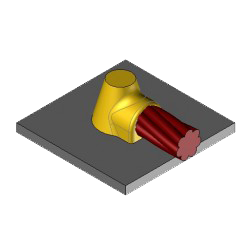

The exothermic metal powder cartridges are calibrated in weight according to the weld to be carried out and contain two types of powder:

- The metal powder is available under the colored cover and consists of a mixture of copper and aluminum oxide and serves as a raw material to fuse with the conductors to be welded

- The ignition powder is available under the black cover and is used to start the fusion process, when igniting the exothermic welding process

► How to choose all the required exothermic welding materials ?

To choose all of the required materials, follow the steps below:

- Select the graphite mold

- Select the handle clamp

- Select the metal powder

- Select the ignition method

- Select the accessories and safety equipments

► What if the welding configuration is not available on MALTEP website ?

MALTEP also manufactures graphite molds for the realization of particular welding configuration.

Do not hesitate to consult us for any particular request with the following welding inputs:

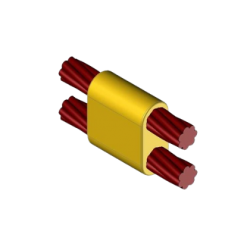

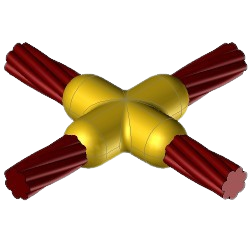

• The configuration of the weld: tee, parallel, etc..

• The nature of the conductors to be welded: cable, round, rebar, etc. (note that aluminium is not suitable with exothermic welding)

• The cross section, diameter, conductors dimensions

• The number of welds to be done for each type of weld

► Wants to know more ?

|

|

Discover our exothermic welding overview |

Data sheet

- {0}

Products that you might need

-

Default

⚡ MALTEP opens E-commerce to neighboring countries ⚡our e-commerce platform is now open to Belgium, Luxembourg, Germany, and Italy

-

Default

⚡ Now online: Welding equipment storage case⚡Protect your welding equipment from handling and storage incidents and make it easy to store.

-

Default

⚡End-of-year closure & best wishes for 2026 ⚡As the holiday season approaches, the MALTEP team would like to warmly thank all our customers and partners for their trust throughout 2025. As every year, we will be taking a winter break to [...]