- Reference

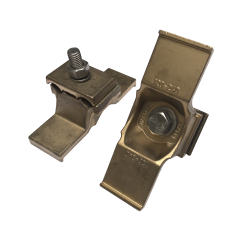

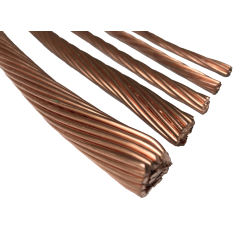

Bimetallic copper and aluminum washers are used to reduce galvanic corrosion between metal parts of different nature causing corrosion phenomenon. The contact between material such assteel/copper, aluminium/copper ou zinc/copper generates an electrochimical reaction that leads to an electrolytic corrosion.

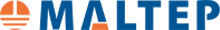

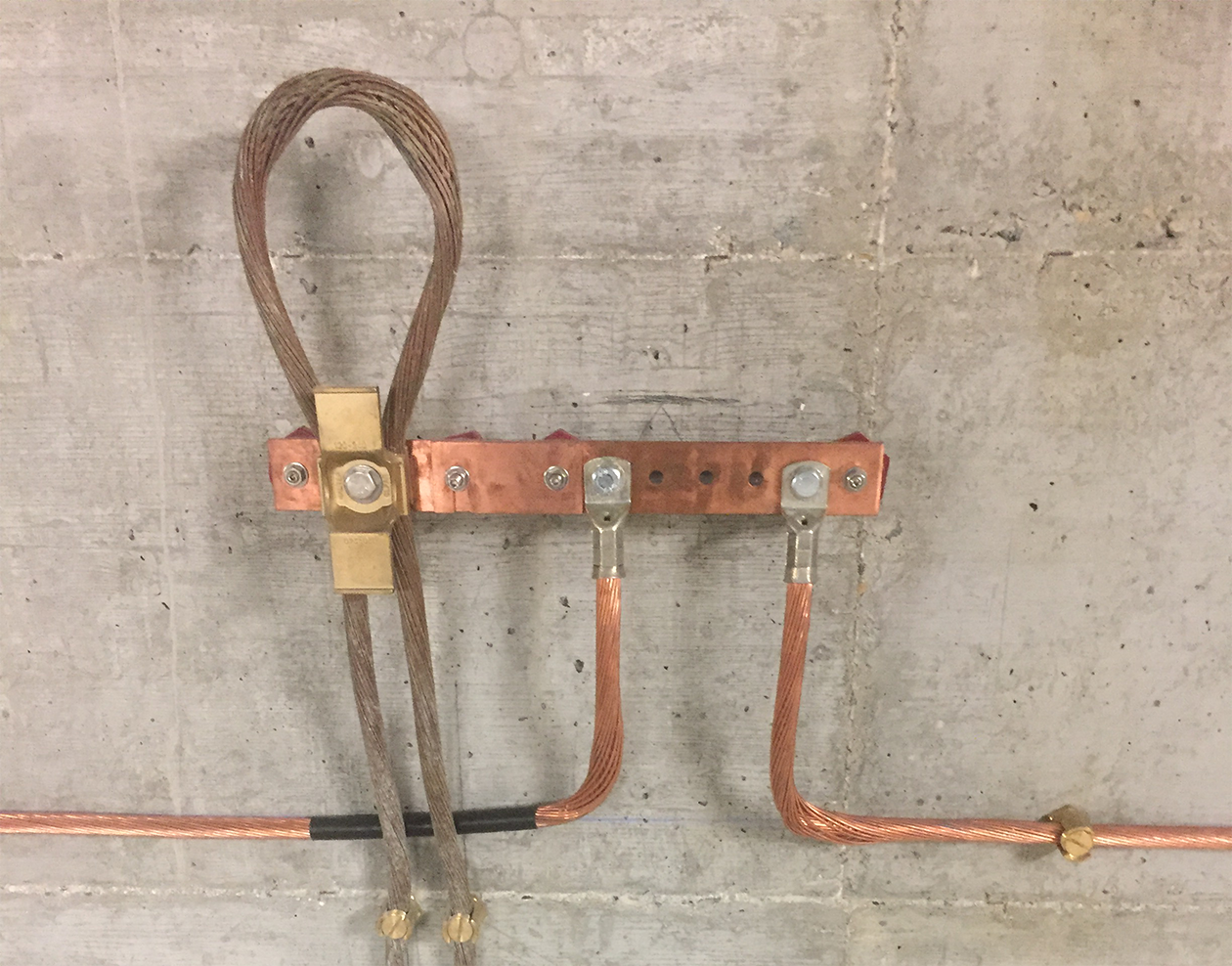

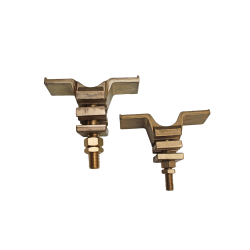

Bimetallic washers place between the grounding/equipotential clamp, such as earth clamps, cable holders or flexible earthing braids, and steel surface onto which they are mounted, reduce the corrosion effect while providing an electrical continuity.

The aluminium side of the washer is installed in contact with the steel frame side, the copper side is installed in contact with the clamp which i susually made of copper or copper aloy such as brass.

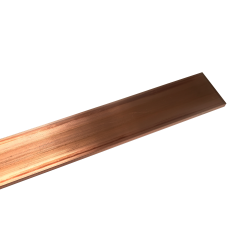

MALTEP offers, as standard, a range of bimetallic washers made of:

- 15% copper

- 85% colaminated aluminum

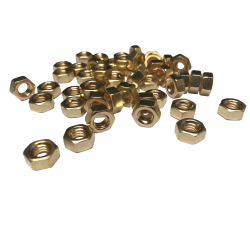

The washers, depending to the choosen model, are suitable from M10 to M16 bolts.

MOUNTING TIP: Check the galvanic compatibility between material before mounting your earthing equipment

To reduce at its best the galvanic corrosion, the best solution is to keep the same material on all the elements of your earthing and grouding circuit. However, this mounting criteria, is often hard to reach on the field. Download our technical note on galvanic corrosion and check the galvanic compatibility.

► Wants to know more?

|

|

Check our galvanic corrosion overview |

Data sheet

- {0}

Products that you might need

-

Default

⚡ MALTEP opens E-commerce to neighboring countries ⚡our e-commerce platform is now open to Belgium, Luxembourg, Germany, and Italy

-

Default

⚡ Now online: Welding equipment storage case⚡Protect your welding equipment from handling and storage incidents and make it easy to store.